Microcement vs Other Surfaces

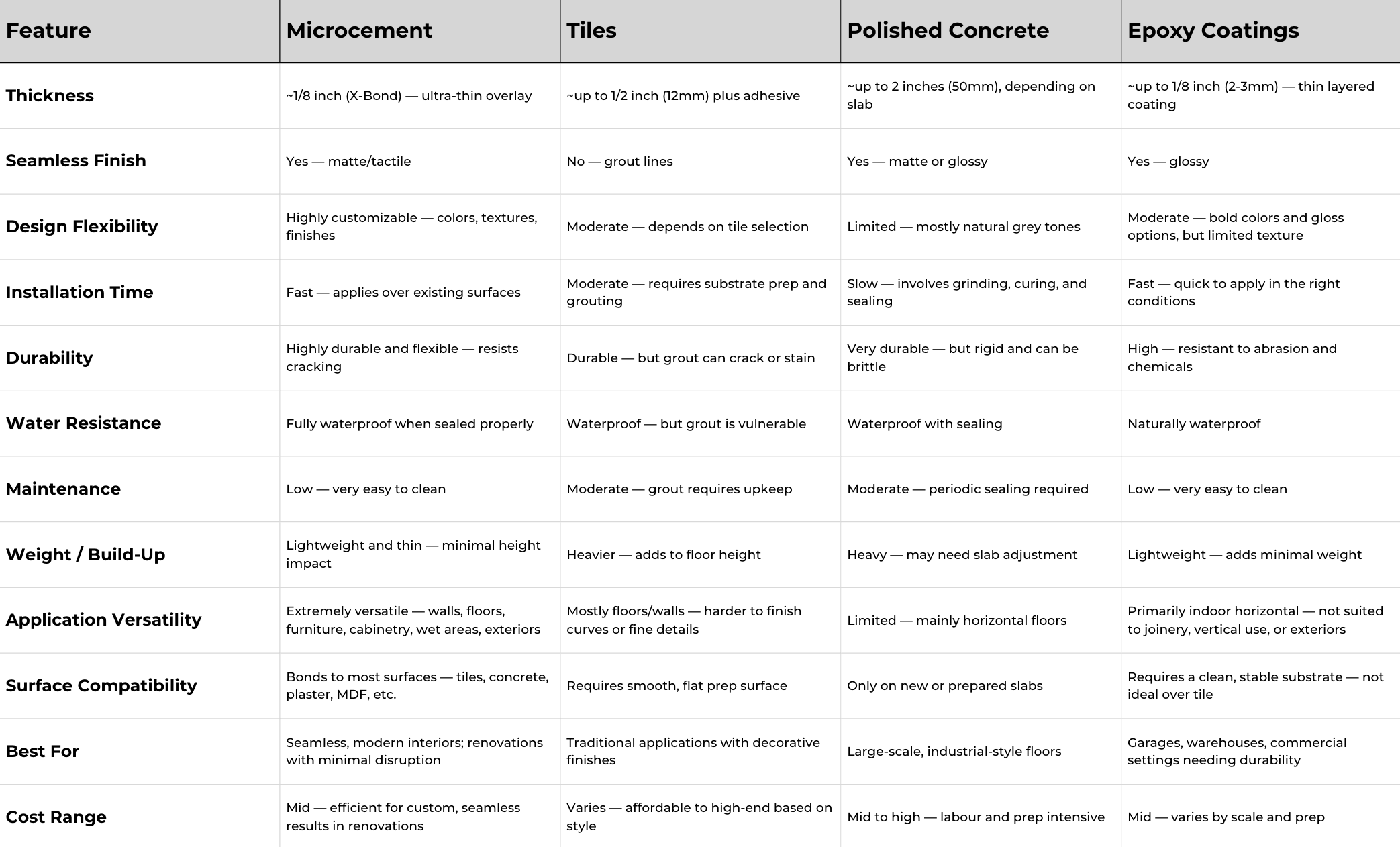

Choosing the right surface material is key to achieving the look, durability, and function you want for your floors, walls, or joinery. Microcement is a modern, versatile option — but how does it compare to traditional surfaces like tiles, polished concrete, or epoxy? Let’s break it down.

Here are the key areas where microcement stands out in comparison to other surface finishes…

Seamless aesthetic across every surface.

Unlike tiles, which require grout lines, or polished concrete and epoxy, which have limited applications, microcement delivers a truly continuous finish across all areas — floors, walls, and joinery. This makes it ideal for spaces where visual flow and minimalism are key, where you want one material specified across all surfaces.

Less demolition, more possibility.

Compared to the other materials, microcement can be applied over the widest range of existing surfaces — including tiles, plasterboard, and concrete — which opens up more possibilities in renovation scenarios. There’s less mess, less waste, and less structural adjustment required because it’s so thin and light, especially when compared to traditional tiling or concrete flooring.

Ideal for wet areas.

When properly sealed and preceded by a liquid waterproofing membrane, microcement is fully waterproof, making it a strong alternative to tiles in bathrooms, showers, laundries, and kitchens. And since it’s applied seamlessly, there are no grout lines to absorb moisture or trap mould, simplifying cleaning and long-term maintenance.

Durable and low-maintenance

Thanks to its flexible formula and molecular bond, microcement resists cracking and delamination when applied over stable substrates. It holds up well to daily wear in high-traffic zones and requires only basic maintenance — usually just routine cleaning and occasional resealing. It’s also able to withstand all climates, temperature fluctuations, and UV exposure for use externally.

None of the other materials can boast this. Tiles are rather fragile, often made from ceramic or glass. Grout lines can also be prone to staining and deterioration over time. Polished concrete is very hard-wearing, but its rigid composition is more prone to cracking with substrate movement than microcement’s flexible formula. Standard epoxy, while a highly resilient surface, can discolor if exposed to UV light or fracture in extreme temperatures.

Wide range of applications.

Microcement is exceptionally versatile. As it’s hand-applied with a trowel, an installer can manipulate the product to coat all kinds of shapes and surfaces. On the other had, tiles are best suited to flat, regular surfaces and aren’t often curved or wrapped around edges without cuts and grout lines. Polished concrete is mostly limited to floors or large slabs due to its weight and application process. Epoxy is commonly used on horizontal surfaces in industrial or commercial settings, not typically suitable for walls, furniture, or exteriors as mentioned above.

Functionality in wet areas.

After waterprooding and sealing, our product X-Bond Microcement is perfect for bathrooms, kitchens, and all other wet areas (be careful — not all microcements are!). This is why it’s a preferred option to tiles where a seamless alternative is desired, offering excellent water resistance but without the need for grout maintenance.

Found what you were looking for? Take me back to the Microcement Hub.