SEALERS

SEMCO Sealer Matte

Engineered for professionals,

installed by anyone

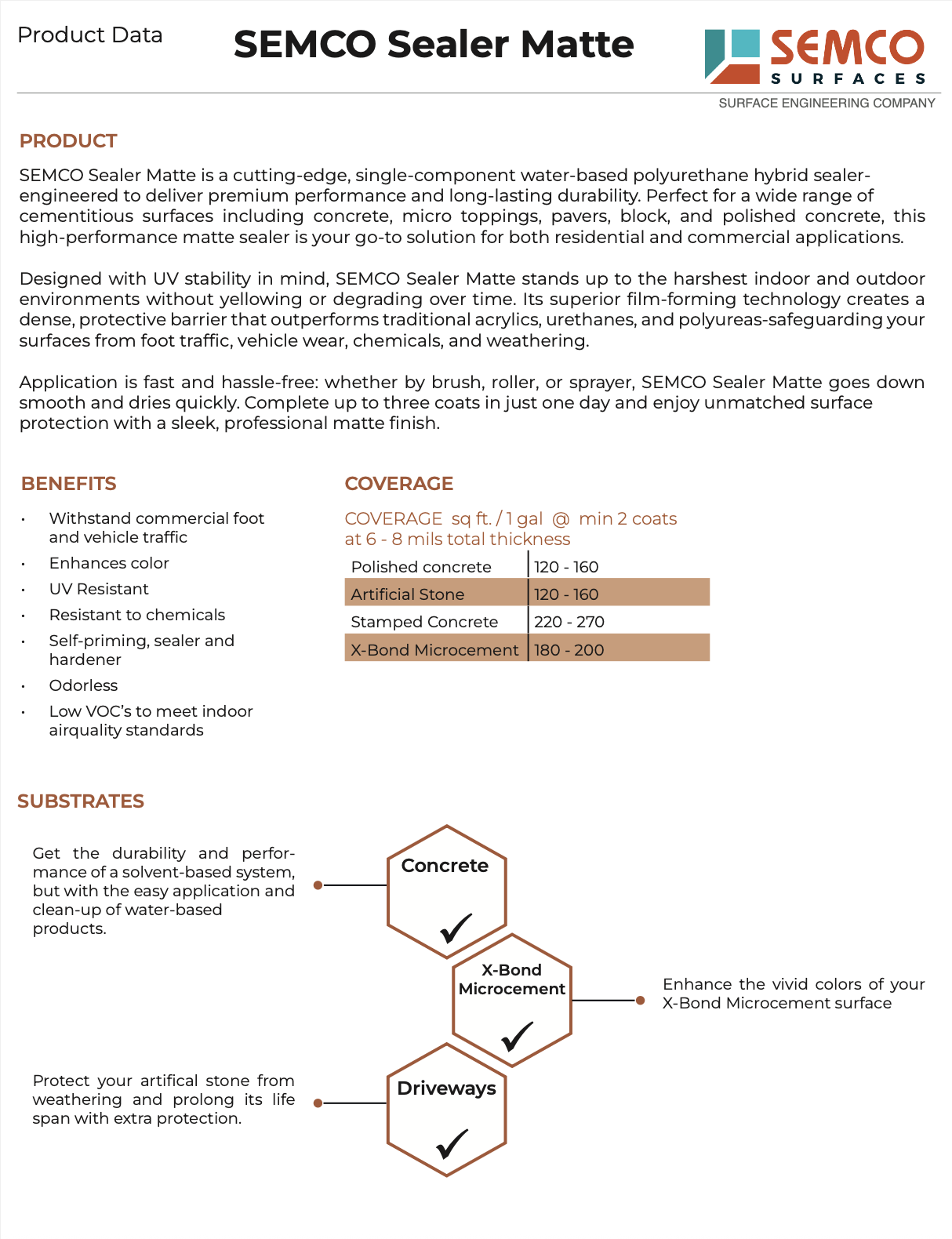

SEMCO Sealer Matte is a single-component, water-based polyurethane hybrid designed for long-lasting protection on cementitious surfaces such as concrete, pavers, blocks, and polished concrete. Its UV-stable formula prevents yellowing or degradation, making it ideal for both indoor and outdoor use.

Advanced film-forming technology creates a dense, protective barrier that outperforms traditional acrylics, urethanes, and polyureas to guard against heavy traffic, chemicals, and weathering. Application is fast and hassle-free: whether by brush, roller, or sprayer, SEMCO Sealer Matte goes down smooth and dries quickly so you can complete up to three coats in just one day.

Features & Benefits

SEMCO Sealer Matte is a self-priming, sealer and hardener in one, suitable for residential and commercial interior and exterior applications. Get the durability and performance of a solvent-based system, but with the easy application and cleanup of water-based products.

RECOMMENDED FOR

Concrete (including polished concrete)

Micro toppings

Pavers

Block

Garages

Driveways

-

With its quick-drying system, a 3 coat application can be easily completed in a single day!

-

Withstands commercial foot and vehicle traffic, as well as chemicals.

-

Enhance the vivid colors of your X-Bond Microcement surface.

-

Won’t yellow or fade in external areas.

-

Odorless and low VOC content to meet indoor air quality standards.

Application Instructions

Airless sprayer

Tip size 17

Magic trowel

Roller

1/4” woven short nap

-

Execute appropriate preparation method to suit your needs before application. Reference to the SEMCO SIP Manual under the Surface Preparation Section.

Test pH level after preparation (optimal pH level is 6.8 - 7.8 )

-

Use airless sprayer with tip size 17 at 850-1,000 PSI. Position the airless sprayer gun at 18” away from the floor

OPTIONAL: Use magic trowel or 1/4” woven short nap roller to apply the product. Do not go back and forth.

Minimum of 3 coats is required to ensure 6 - 8 mils total film thickness

-

Apply the SEMCO Sealer Matte with a woven 1/4” nap roller and use Magic trowel to spread it evenly. Start from top to bottom. Minimum of 2 coats is required. Use HVLP with a large tip size 17 to apply SEMCO Sealer Matte on large surface areas.

Notes

Extended application procedures can be found in the SEMCO SIP Manual.

Procedures for cleaning of the flooring system during operations can be found in the SEMCO SIP Manual or upon request

Safety Data Sheets for SEMCO Sealer Matte are available upon request.

Over time — due to normal wear, abrasion, traffic and cleaning — generally, high gloss coatings are subject to a reduction in gloss, while matte finish coatings can increase in gloss level under normal operating conditions.

Excessive service conditions, such as steel- or hard plastic-wheeled traffic or dragging heavy metal equipment or loaded pallets with protruding nails over the surface, are categorized as misuse and abuse.

Allowances must be made for scratches or abrasions that occur due to moving or sliding furniture or fixtures over the surface

Specifications

COVERAGE

sq ft / 1 gal @ min 2 coats at 6 - 8 mils total thickness

| Polished concrete | 120 - 160 |

| Artificial Stone | 120 - 160 |

| Stamped Concrete | 220 - 270 | X-Bond Microcement | 180 - 200 |

PRODUCT DETAILS

| Color | White/milky liquid | Application | Airless sprayer, tip size 17", 1/4" woven short nap roller or Magic Trowel |

| Application Environment | Apply at tempreatures from 50F to 90F |

| Chemical type | Polyurethane hybrid |

| Clean up | Stone Soap and water |

| Shelf life | 1 year (ambient temperature of 60°F - 72°F |

| Packaging | 1 gallon, 5 gallons |

DRYING TIMES

Drying times are affected by temperature and relative humidity. The chart represents guideline values but each project is to be treated individually. Below is the general time needed in between coats at a specified temperature.

CURING TIMES

Curing time is affected by temperature and relative humidity. The chart represents guideline values but each project is to be treated individually. For example, at only 45°F a full cure would take 48 hours. In comparison, at 90°F it would only take 18 hours to cure.

LABRATORY TEST RESULTS

| Used automobile oil | Excellent | Transmission fluid | Good |

| Cooking oil | Excellent |

| Alkali resistance | Excellent |

| Hydrolic acid (10%) | Good |

| Wine | Excellent |

TECH SHEET - SEMCO SEALER MATTE

View Project Gallery